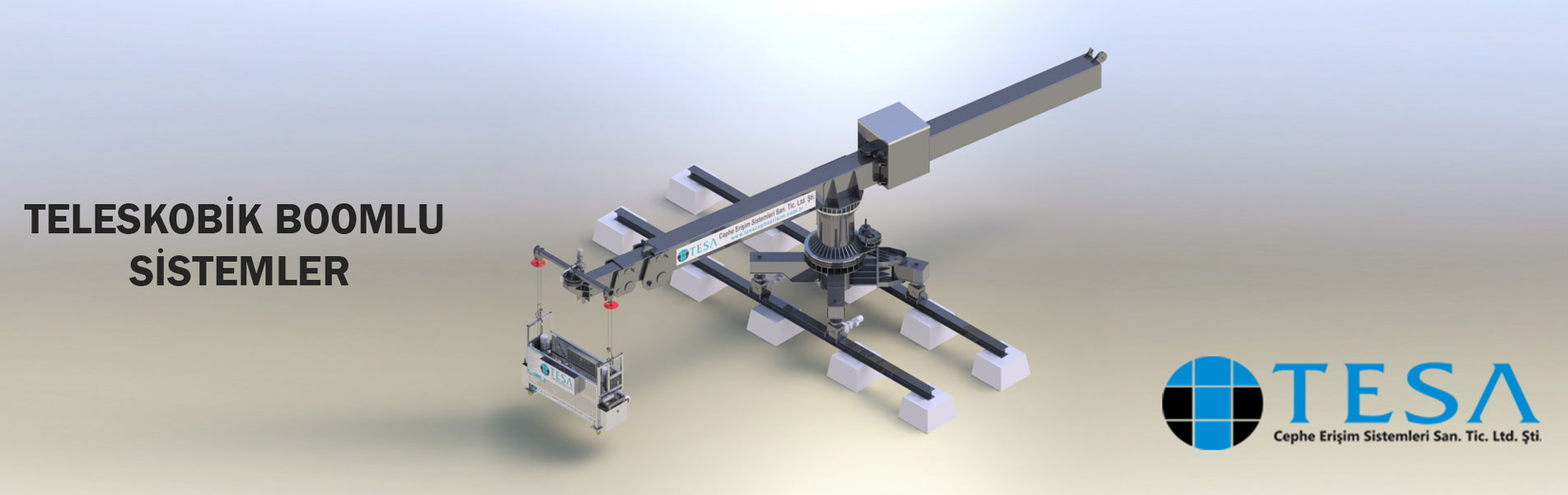

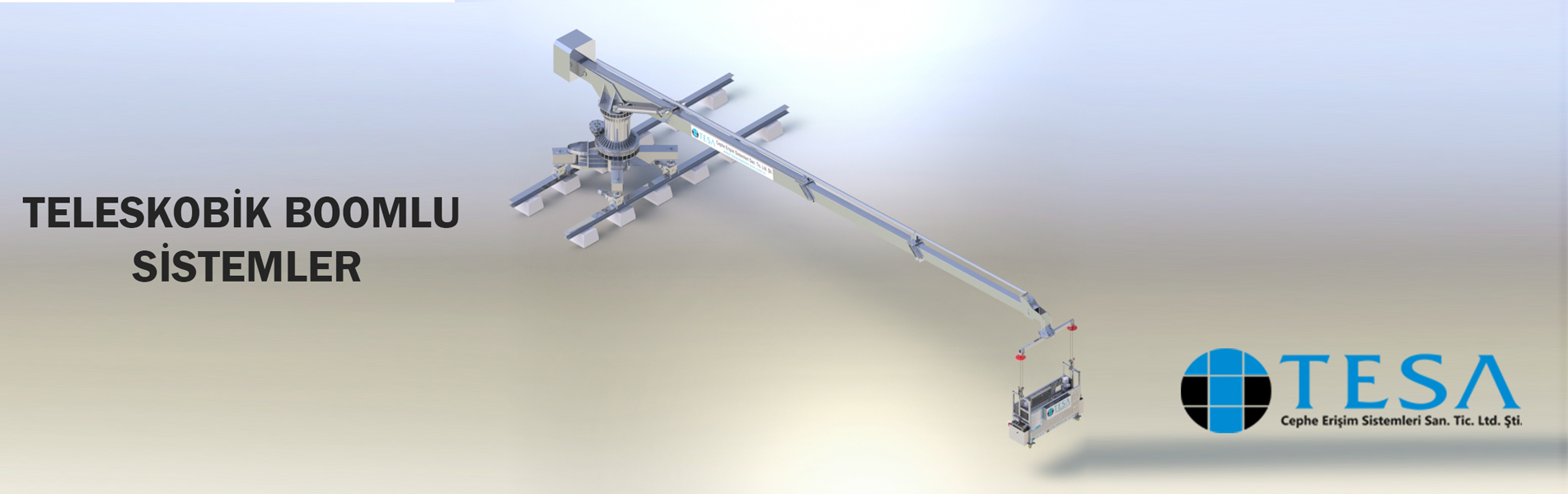

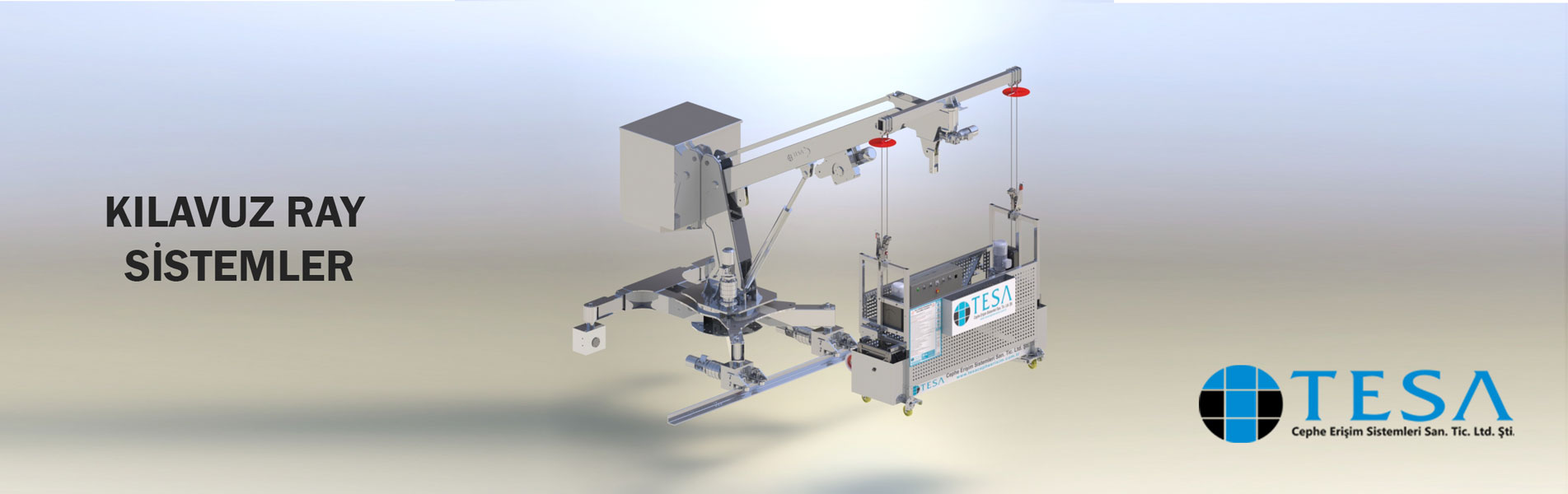

It is possible to adjust the working gap between the cradle and the facade by means of the hydraulic movement of the boom.

After the cleaning process is over, the basket is parked on the terrace.

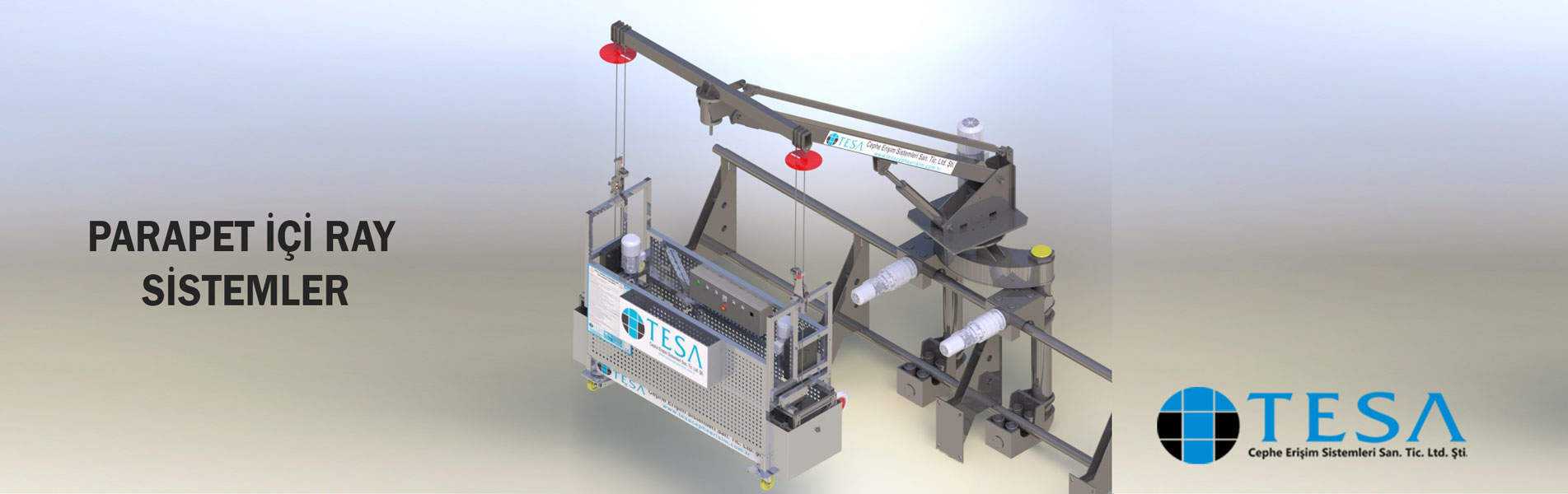

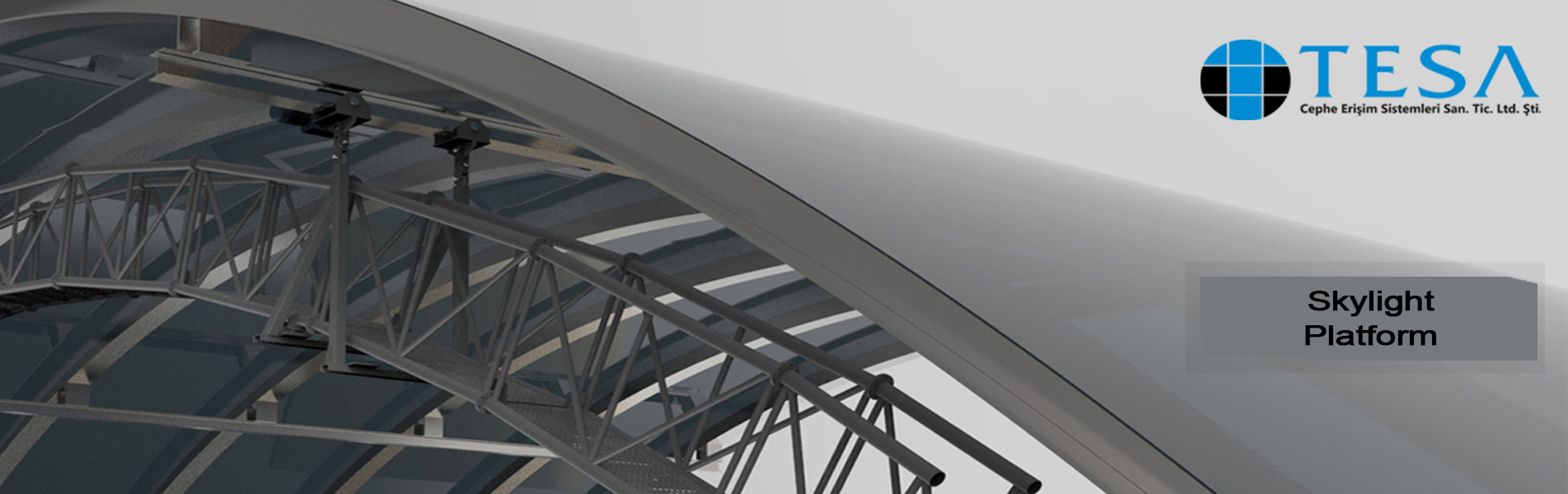

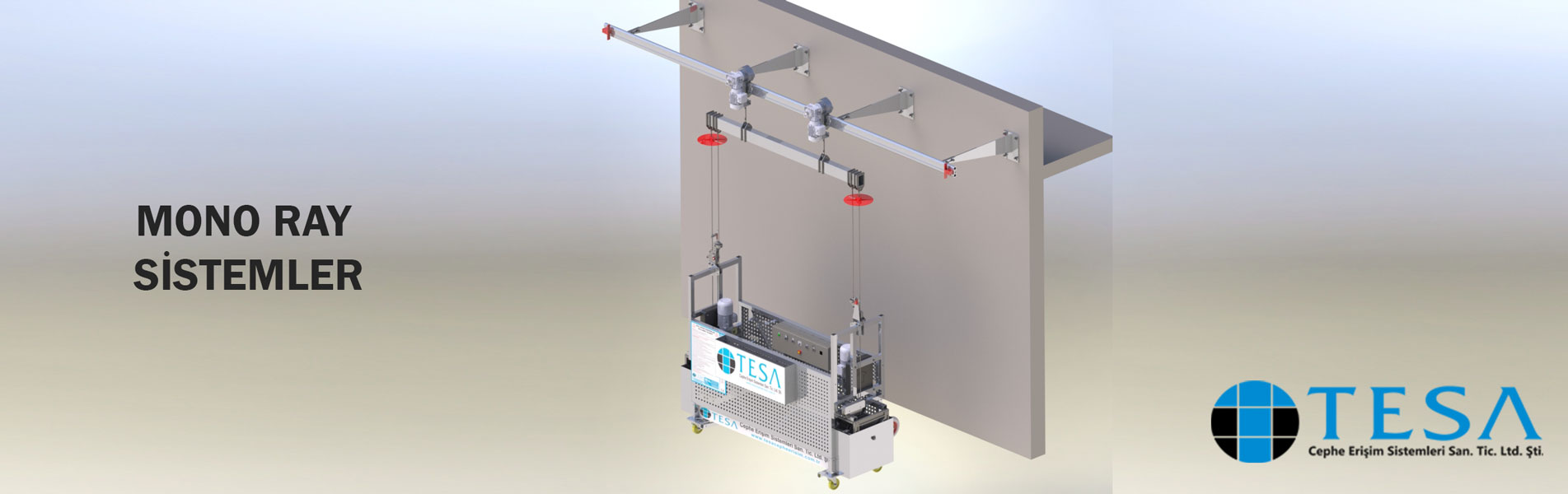

During operation, the system is equipped with a terrace rail so that the system can be used without damaging the building.

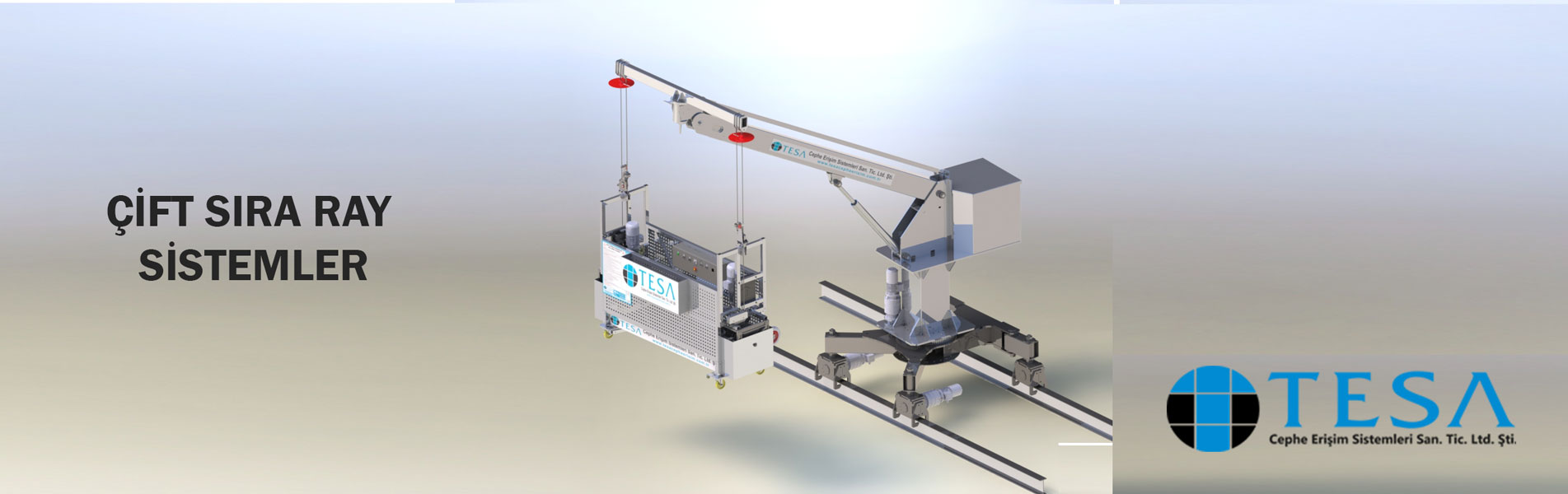

The selection of rail types and other equipments suitable for the architectural structure of the building is examined by our technical staff in place and the alternative solutions are presented together with the cost, and the decision maker is suggested optimum solutions.

Thanks to telescopic boom, it is possible to reach the desired working distance from one point.

It is possible to reach all the facades of the building by double row rails laid on the deck.

The system moves horizontally at a speed of 5 cm / sec on the rails.

380 Volt energy required during horizontal movement is provided with trolley closed finger bars and motion continuity is gained.

In this case, the risk of cable transferring and crushing of the cable has been removed.

A total of 12 movements can be controlled from the desired point with the wireless remote control.

1) Compass group; Mechanism with stop switch at the end of the tour which can turn 340 degrees.

2) Boom group; Standard type, size can be adjusted according to building.

3) Boom lifts; 2 with upper and lower limit switch.

4) Belly return unit; It can turn 340 degrees, end stop switch with tour.

5) Hydraulic unit; The hose is explosion-proof.

6) Counterweight group; It is produced from hair, cast or concrete according to the machine type.

7) Body group; Corrosion-resistant all steel construction.

8) Carrier (Walking) group; There are 2 pylons, 4 without pylons, double rail type.

9) Cradle group; It is variable type according to machine and building type, there is a basement safety bar.

10) Balance rod group; Works synchronously with compass and body.

copyrights reserved © Markaca.net